Chevron Phillips

Chevron Phillips

During this crisis our industry is giving back to help others in need. Hear their stories. Share their stories.

Chevron Phillips Chemical employees make quality products needed during COVID-19 battle

In the ongoing battle with COVID-19, Chevron Phillips Chemical is blessed with caring, dedicated and performance-driven employees.

Throughout the company, employees are working hard to continue business as usual during this challenging time. Our response is an ideal example of our tagline: Performance by design, Caring by choice. It is how we do business, our culture and our way of life at work.

“It takes everyone from Manufacturing to Supply Chain to our Technical Center and all the supporting roles to meet increased demand,” said David Morgan, senior vice president for polymers and specialties. “Everyone’s contributions are valued and being noticed.”

Managers across the enterprise also have their fingers on the pulse of their customers’ needs and are being flexible to meet the most pressing demands.

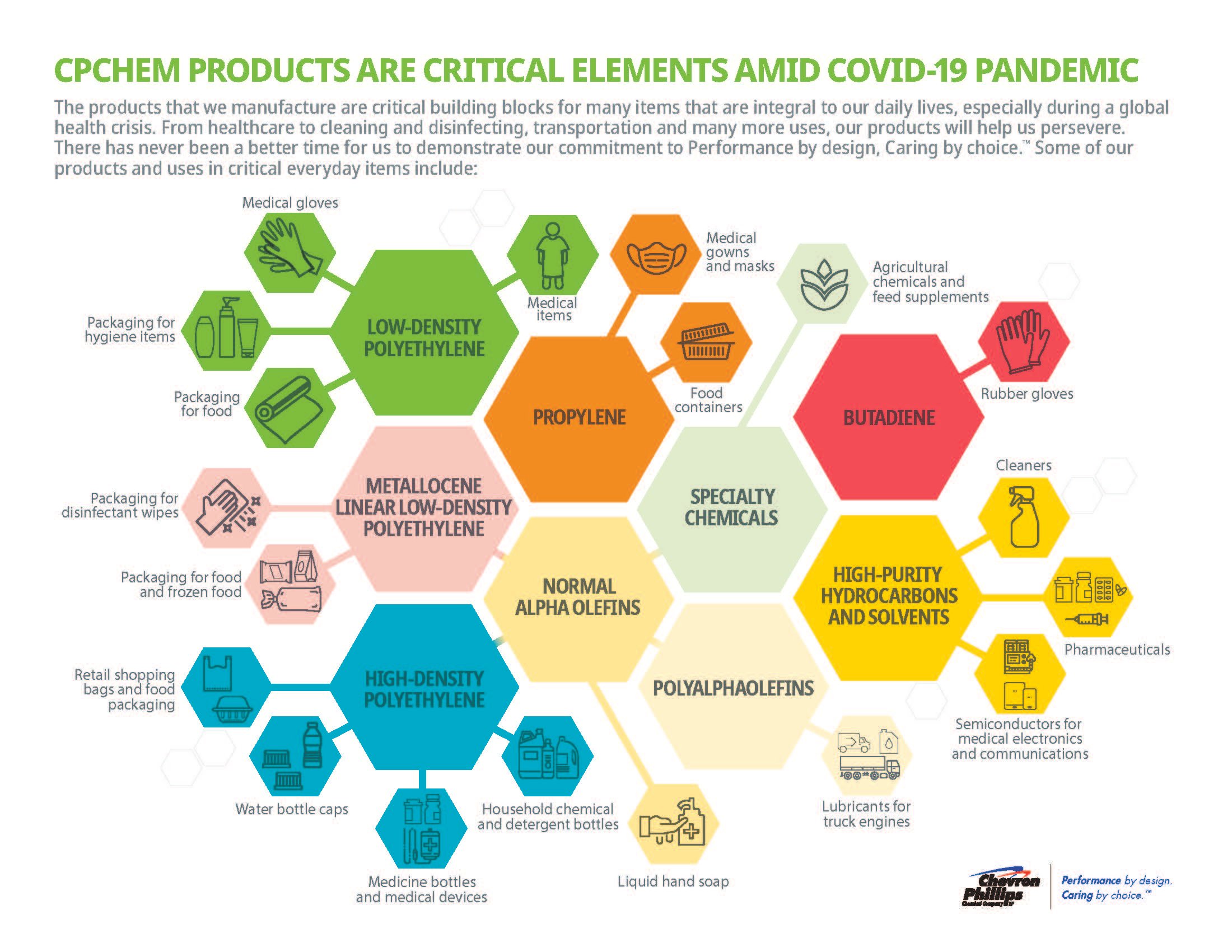

“We are a key supplier of high-density polyethylene used to make liquid food containers and household chemicals in the U.S. and Canada,” said Jason Ormes, marketing manager, Polymers. “Our production and planning teams have been working hard to produce additional volume to meet growing demand during this crisis.”

Customers use our resins to make packaging for and in the production of a multitude of items, bleach and hand sanitizer among them. Ormes explained that both are in high demand and needed in large quantities for disinfectant use against COVID-19. Customers are also using our products to create COVID-19 test kit packaging, tote containers which store alcohols vital to the production of hand sanitizer, and disinfectant wipe bottles.

Jim Addcox, a marketing manager for Marlex® polyethylene who works primarily in flexible applications, echoes the increase in demand for our products.

“In flexibles, customers use our Marlex® polyethylene products across a wide array of consumer and food packaging applications that you see in grocery stores,” Addcox said. “Examples include cereal and bakery packaging, standup pouches and snack food packaging, frozen food and meat packaging, as well as paper towel and toilet paper overwrap.”

Our Marlex® polyethylene products must meet FDA food packaging requirements and are on the front line of food protection. With millions of people on “stay home” orders, almost no one is eating in restaurants. They are going to the grocery store, ordering takeout or having food delivered. The safety and integrity of the food chain – from farm to table – is critical.

“We serve hundreds of customers, and the world is extremely dependent on a food logistics stream that is reliable and protected from external contamination, including COVID-19,” Addcox said.

“We are also are seeing an uptick in demand for single-use plastic shopping bags,” he continued. “For years, people have been encouraged to use reusable shopping bags to carry their groceries. Over the past few weeks, though, stores have discouraged, and in some cases, disallowed customers from bringing reusable bags into stores because studies have shown these can be a source of viral contamination. We are seeing a nationwide trend back toward single-use plastic bags, which in many areas can be recycled or used in lower-risk secondary applications and have been shown to have a lower environmental impact than paper alternatives.”

Our products are also part of the supply chain for critical items such as personal hygiene and medical packaging.

“We are seeing atypical uses of PE films and sheeting, for example, as screens to cordon off areas in hospitals and other public venues where the risk of exposure to COV-19 is elevated,” Addcox said.

Our Specialty Chemicals business also makes several critical components used by customers to create products needed during the COVID-19 challenge.

“We make chemical intermediates used by customers to formulate agricultural chemicals and animal nutrition feed supplements that are critical for the national and global food supply of produce and meat,” said Stephen Landry, business manager, Specialty Chemicals.

Other key specialty chemicals that are especially important during the COVID-19 crisis include Heptane, a pharmaceutical intermediate for the Tamiflu® medication and used in cleaning solvents for medical, laboratory and electronics use.

Our Methyl Mercapto Propionate (MMP) is used in the production of non-oxidizing biocides to prevent the formation of fungi and bacteria in personal care and paper products.

Our Soltrol® solvents are used in the formulation of household cleaning products, and Sulfolane-E is used in the etching of semiconductors that are often part of various medical electronic and communications applications.

“Customers have asked us to maintain reliable supply or increase production of these critical components, and our Specialty Chemicals team, especially our manufacturing facilities are rising to meet the call,” Landry said. “We are willing and able to meet the demand for these products and will do our part to help in the battle against COVID-19.”

Our response to COVID-19

As COVID-19 continues to make an impression around the world, the safety of our employees, contractors, customers and communities is of the utmost importance to us. Measures are being implemented at our facilities and administrative offices globally.

Personnel Safety

The health and safety of our employees and contractors is a core value of our company. We have taken numerous steps to ensure a healthy and safe work environment, including:

- Providing current information and updates on our internal COVID-19 site

- Travel restrictions applied at all our facilities, including international and domestic travel

- Fully activated social distancing for all personnel and remote connectivity where applicable

- Increased sanitization measures and frequency at all locations

- Establishing screening processes (including temperature checks) for early detection

Implementation timing across the regions in which we operate has varied, as appropriate depending on local conditions and the advice of public health authorities.

Planning & Preparedness

Business continuity plans are in place for all our sites and regions. We are actively monitoring the rapidly developing situation and applying these plans as warranted. These plans are coordinated globally with an intent to minimize any potential disruptions to our customer base.

Facility Operations

Numerous locations around the world have, where possible, implemented a split-shift schedule. Separate shifts are directed to not make physical contact with each other, to minimize the impact to the business of a widespread outbreak.

About Chevron Phillips:

At Chevron Phillips Chemical, we believe that real benefits can be gained by establishing effective relationships in our communities. That is why the corporation donates funds to worthy causes and we encourage employees to similarly make a positive impact. Since the company’s inception, Chevron Phillips Chemical has invested more than $15 million (and countless volunteer hours) in communities where we live and work. In all, we recognize that establishing sound partnerships with our neighbors – in our international, national, and local communities – provides for a lasting relationship built on trust and goodwill.

Learn More: http://www.cpchem.com/